Cut edge corrosion is one of the most prolific cladding problems we see at GI Sykes. It’s not always preventable, but with careful maintenance, your cladding can avoid the costly damage it causes.

But what is cut edge corrosion and what can you do to avoid huge cladding repair bills?

Cut Edge Corrosion: The Facts

Cut edge corrosion refers to the decay that happens to the edges of your metal cladding. Metal cladding is used predominantly on industrial buildings thanks to its durability and clean aesthetic, but over time the edges of the metal sheets can become damaged.

The edges of your cladding are a weak spot, more prone to problems than any other area. The corrosion often starts as a small breakdown of the metal but can quickly escalate into a sizable area – putting your building at risk.

How to Spot Cut Edge Corrosion

Before you dash off to check if your cladding is suffering cut edge corrosion, it’s best to see what you’re looking for. Firstly, you need to identify the edges on your cladding – these are usually easy to spot because they have bolts running alongside them.

Cut edge corrosion usually starts with peeling paint or coating, so if you’re lucky, this is the stage you’ll discover the issue. However, unless you’re investing in regular maintenance, you are unlikely to find the damage until it’s progressed to rust.

The extent of the rust will determine just how big of a problem you have on your hands. Caught early, the repair is straightforward. But left too late, you may find yourself needing to replace your cladding entirely.

What Causes Cut Edge Corrosion?

Problems with your cladding can happen for a variety of reasons. Some can be prevented while others need to be watched for. The main reasons we see cut edge corrosion in our line of work are;

Poor Manufacturing Quality

Cut edge corrosion can start right from the beginning of your cladding’s lifespan. Poorly made cladding sheets often have exposed metal edges that quickly begin to deteriorate when put in place. The best tip we have when purchasing new cladding is to buy the best quality you can afford and always inspect the edges to ensure that they are coated.

Weathering

Your cladding is there to protect your property from the damaging effects of the weather, so it’s no real surprise that those effects can create problems with your cladding.

The weather in the UK is highly varied – there are long months of damp, windy days with freezing temperatures followed by months of bright, (sometimes!) hot sunny days. Although cladding is made to withstand weathering, over time harsh UV rays can cause the coating on your cladding to become brittle and crack, with the edges being worst affected. Frost and rain can then make contact with the unprotected metal where it begins to degrade.

Damage

Bumps, scrapes and collisions can cause your cladding to delaminate, creating weak spots where water can get in. When this happens near the edges of your cladding, the damage can be even more significant as the coating is more likely to split or crack.

Environmental

Where your property is located can have a bearing on the severity of your cut edge corrosion problems. Those in coastal areas will find the salt in the air causes corrosion to occur at a much quicker rate.

Similarly, buildings that are in highly populated areas will suffer the effects of pollution more. The chemicals and exhaust fumes in the air mix with oxygen, and in doing so have a corrosive effect on exposed metal.

Ageing

While careful care of your cladding can help to avoid issues such as cut edge corrosion, they are only avoidable for so long. Ageing metal will wear and degrade over the years, so it is to be expected that some cladding panels will need to be replaced once they reach their limit of damage.

Improper Care

If you ignore your cladding, then the likelihood of cut edge corrosion is much higher. Also using the wrong cleaning products or coatings can create bigger problems, losing you both time and money.

What Are The Risks Of Leaving Cut Edge Corrosion Untreated?

Leaving cut edge corrosion untreated is unadvisable. Aside from making your building look tatty and unkempt, the rust will begin to eat away at your cladding which can leave your internal walls vulnerable.

Water ingress can wreak havoc inside your property, resulting in damp, mould and serious structural decay.

Treating Cut Edge Corrosion

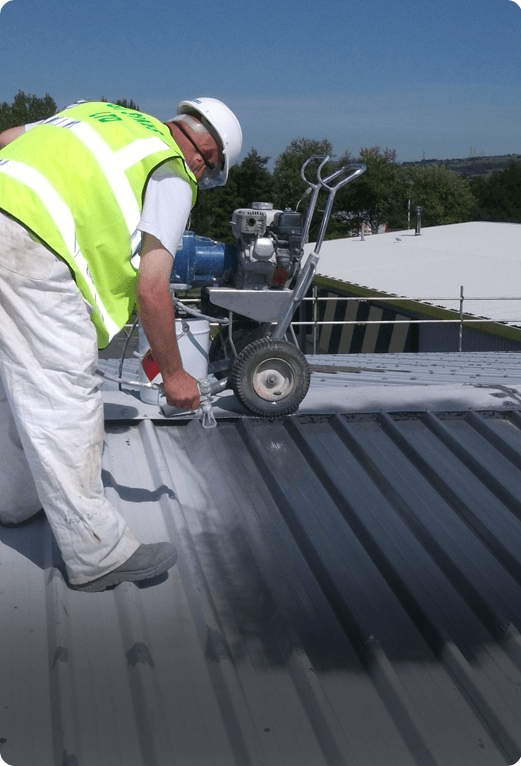

Thankfully, treating cut edge corrosion is a simple process. At GI Sykes we use the industry’s leading anti-corrosion systems to protect and preserve your cladding.

Our team of cut edge corrosion specialists will identify areas of concern and create an action plan that is designed to manage all stages of corrosion. While the process is very detailed and thorough, we are always mindful of minimising disruption to your business.

Once your cut edge corrosion treatment is complete, you can be assured that your cladding will be robust enough to withstand weathering and pollution for many years to come.

Avoiding Cut Edge Corrosion

Regular Inspection

As the saying goes, prevention is better than cure. So if you want to avoid cut edge corrosion and the associated problems that arise from it, then you need to have a regular cladding inspection schedule in place.

This needs to be more in-depth than eye-balling it from the ground, as early cut edge corrosion signs can be slight and easily missed from a distance. Our scheduled property maintenance service allows for careful and close inspection by experts who know what to look for.

Cladding Cleaning

Keeping your cladding clean can help to prolong the integrity of the coatings. It also increases the opportunity for spotting issues as they manifest, rather than later done the line when they become more troublesome.

Specialist Coatings

We use coatings that have been specifically formulated to prevent cladding deterioration and techniques to restore or repair areas affected by cut edge corrosion.

By investing in this service, your building will benefit from a much longer lifespan with cladding that looks clean and well-maintained with well-preserved edges.

Problems With Cut Edge Corrosion?

If your property is suffering with cut edge corrosion or you’d like to take preventative measures, get in touch with the team to discuss how GI Sykes can protect, restore and prolong your building’s metal cladding.